Lean Solutions Group has spent the last decade building its reputation as a people-first partner in the logistics industry. Its embedded teams became fixtures inside freight brokerages, 3PLs, and carriers across North America, powering back-office operations and customer service functions with nearshore talent.

But the company’s newest technology announcements, LeanTek AgentEdge and LeanTek Connect, signal a deliberate evolution. Lean is no longer just adding people to its customers’ operations; it is designing the technology that shapes how those people work.

CEO Jack Freker is straightforward about the shift. The company still deeply values its roots in staffing, but those roots now fuel something larger. “It’s a different Lean than five or ten years ago,” he said.

While the company once saw demand primarily for people augmentation, its embedded operators gained a front-row view into how freight operations really function. Lean saw the repetitive tasks that slowed teams down, the workflow gaps that caused errors, and the decision points where experience mattered more than automation. “This evolution is not just people, it’s technology. We’re empowering their teams with AI and improved workflows. It strengthens how teams work and their outcomes.”

Lean’s growth reflects that vision. With more than 10,000 employees across five countries and around 600 customers, most in logistics, the company is blending its process knowledge with the kind of tech development once reserved for venture-backed automation startups.

The difference, Lean argues, is that many software players aren’t native to supply chain operations and therefore overestimate what freight teams are ready for. “Everyone wants big results immediately,” Freker said, “but most organizations aren’t ready to make those changes. It’s a journey, not a destination.”

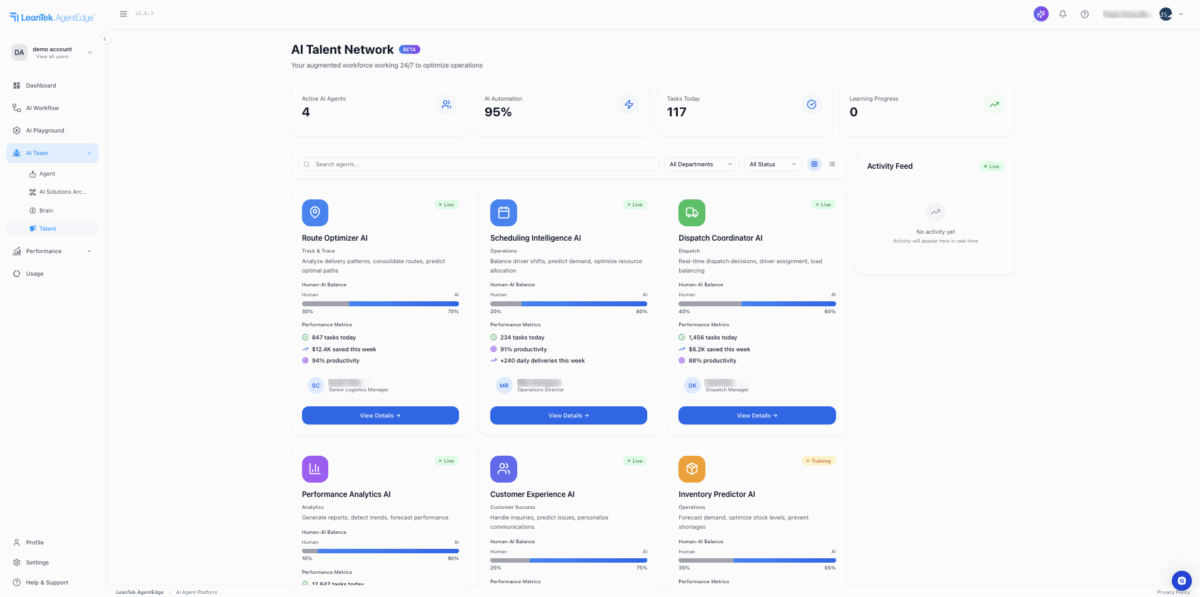

AgentEdge, Lean’s AI-enabled workflow platform, was built with this reality in mind. It is designed to be introduced gradually, starting with the tasks and workflows that are most likely to succeed with automation. According to Freker, customers want the benefits of AI, faster processing, fewer manual touches, predictive insights, but often lack the internal readiness. Lean has begun each deployment by assessing where AI can realistically take hold, not where it merely sounds impressive.

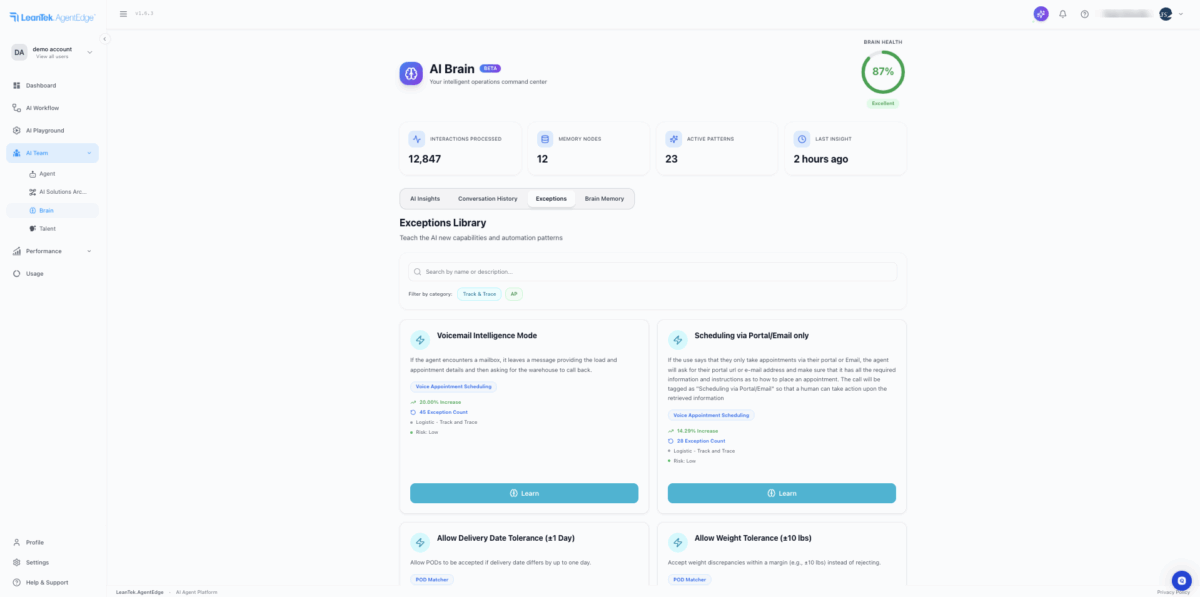

Alfonso Quijano, one of the leaders shaping LeanTek’s technology strategy, says this practical approach is exactly why adoption is accelerating. Logistics, he notes, is not a highly standardized environment. Exception rates are high, and customer interactions require nuance. “The idea that you can just throw an AI into the system and have it manage your most critical processes is crazy talk,” he said. The future Lean envisions is not one where AI replaces operations teams but one where human workers gain new skill sets as they train and interact with AI. In an industry where burnout is common, Quijano says introducing modern tools can make day-to-day work more engaging.

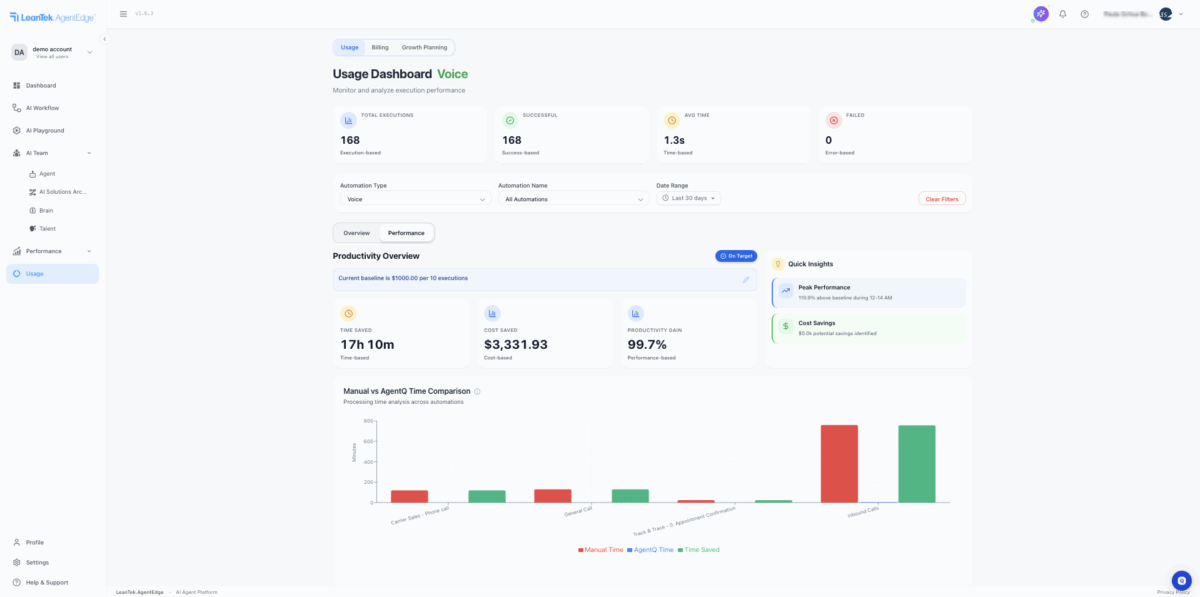

The results, Lean argues, speak for themselves. The company says it has held more than 80 AI-readiness conversations this year that have all converted into active implementations. In one case, a customer automated more than 200,000 invoices with a 90% success rate. Lean attributes that success to knowing which processes are stable and structured enough for automation before deploying any technology.

While AgentEdge focuses on the work itself, LeanTek Connect aims to give leaders better visibility into the people performing it. With distributed teams spread across nearshore and domestic locations, many logistics companies struggle to understand productivity, workflow bottlenecks, and performance across departments. Connect provides a unified view that helps operations leaders understand how their teams function day to day. But Freker emphasizes that visibility does not mean fully automating people out of the process. “Not everything can be automated,” he said. “There will always be areas requiring human intervention.”

The company expects this hybrid approach, pairing people, process expertise, and AI, to become standard in logistics over the next few years. Freker says Lean is doubling its developer workforce to meet demand, but always with the belief that technology should be built around how logistics teams already work, not the other way around.

“You can’t be a broker that only does technology,” Quijano said. “This is a customer-centric industry. You have to manage with care, and care is the human part.”

The post Lean Solutions Group moves beyond staffing with AI-driven workflow and workforce intelligence appeared first on FreightWaves.